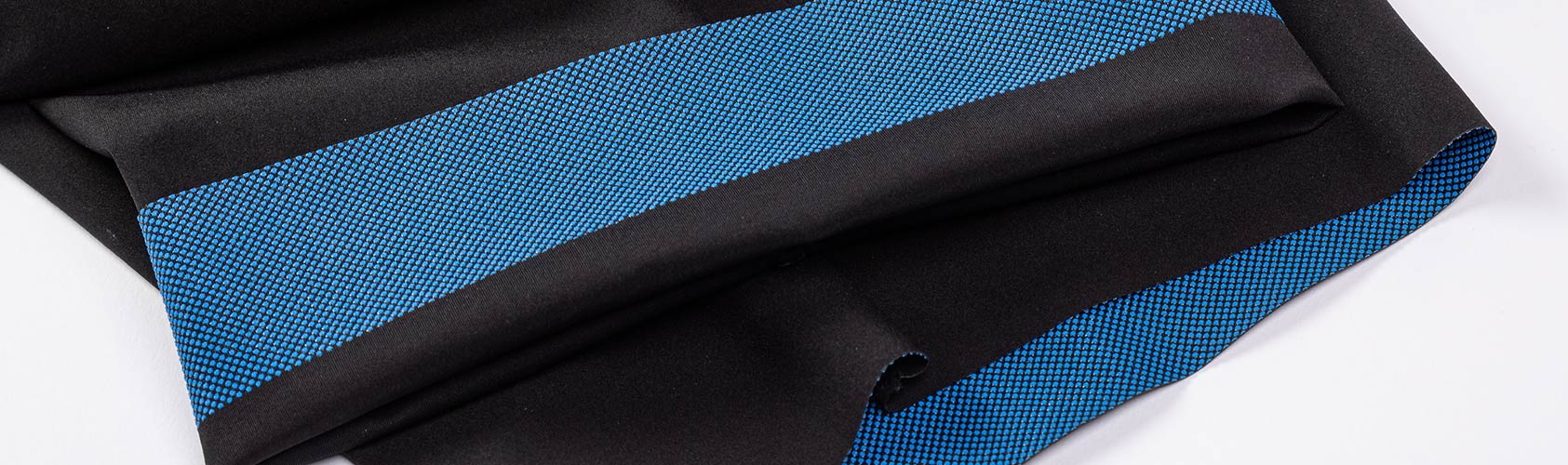

Tailor-made stretch fabrics for every application need

MAB custom elastic fabrics are designed to meet specific functional, aesthetic, and production requirements — offering both performance and brand identity.

Made from synthetic fibers such as polyamide, polyester, and elastomer, they are developed on crochet, jacquard, or Raschel-tronic looms to achieve the ideal combination of elasticity, lightness, and resistance.

Available cut to size or in full widths up to 1500 mm, our custom technical textiles are optimized with finishes tailored to each sector — from fashion to sportswear, from workwear to technical underwear.

We develop custom elastic fabrics, supporting you in every stage of the process

- Application analysis and technical study

- Definition of blend and elastic behavior

- Sector-specific technical proposals

- Design of patterns, effects, and stretch fabrics with print or logo

- Integrated and flexible Made in Italy production

- Continuous quality control at every stage

- Pantone color matching, customer samples, or color charts

- OEKO-TEX® Standard 100 Class 1 and GRS certifications

- Full batch traceability

- Custom-made elastic fabric production for evolving markets

- Ongoing updates on materials and technologies

- R&D support for special projects

- Co-development with brand partners and design teams

Advanced processes for high-performance custom stretch fabrics

Every MAB custom elastic fabric is developed through a detailed analysis of the final application.

We adjust elasticity, thickness, and hand feel to meet specific needs: compression and comfort for sportswear, softness and breathability for underwear, durability and resistance for workwear.

Our in-house dyeing facility ensures Pantone or customer color matching, with batch control for color consistency and long-term reproducibility.

Available finishes include C0 water-repellent treatments, antimicrobial coatings, soft-touch effects, and 3D silicone screen printing for tactile or functional performance.

All processes and materials comply with OEKO-TEX® Standard 100 Class 1, and GRS-certified recycled yarns are available upon request.

Full supply chain traceability and inline controls guarantee consistent quality, reliable lead times, and waste reduction in production.

Custom stretch fabrics for every industry

Technical support and industrial continuity

At MAB, the management of custom-made elastic fabric production is designed to guide each client through every stage — from concept development to serial manufacturing.

We provide dedicated sampling, starter packs, and complete technical sheets to facilitate testing and internal validation.

Thanks to our flexible organization and controlled vertical production, we ensure stable supply, color repeatability, and a competitive time-to-market, even for personalized or high-volume productions.

Decades of specialization in custom stretch fabrics for brands worldwide.

Each project is validated through real testing and developed in synergy with the client.

Stretch fabrics with print or logo, dedicated blends, exclusive colors, technical finishes, and custom textures designed to match each brand’s identity.

Advanced weaving systems — shuttle, warp-knitting, Jacquard, and Raschel-tronic — plus 3D silicone printing, continuous screen printing, technical coatings, and clean cutting systems for precise results.

State-of-the-art printing machines, GRS-certified materials, X-Rite color development systems, and partnerships with research centers and universities to create high-performance custom elastic fabrics.