A High-Performance Edge Binding for Modern Outdoor, Urban & Technical Design

In today’s outdoor and urban-performance markets, every component contributes to the product’s durability, comfort, and brand identity. MAB developed Art. 5691-20 mm to respond to the growing demand for materials that combine technical reliability, a clean aesthetic, and long-lasting performance — even under intensive use.

Why Art. 5691-20 mm Stands Out

Designed as a next-generation technical edge binding, this material offers:

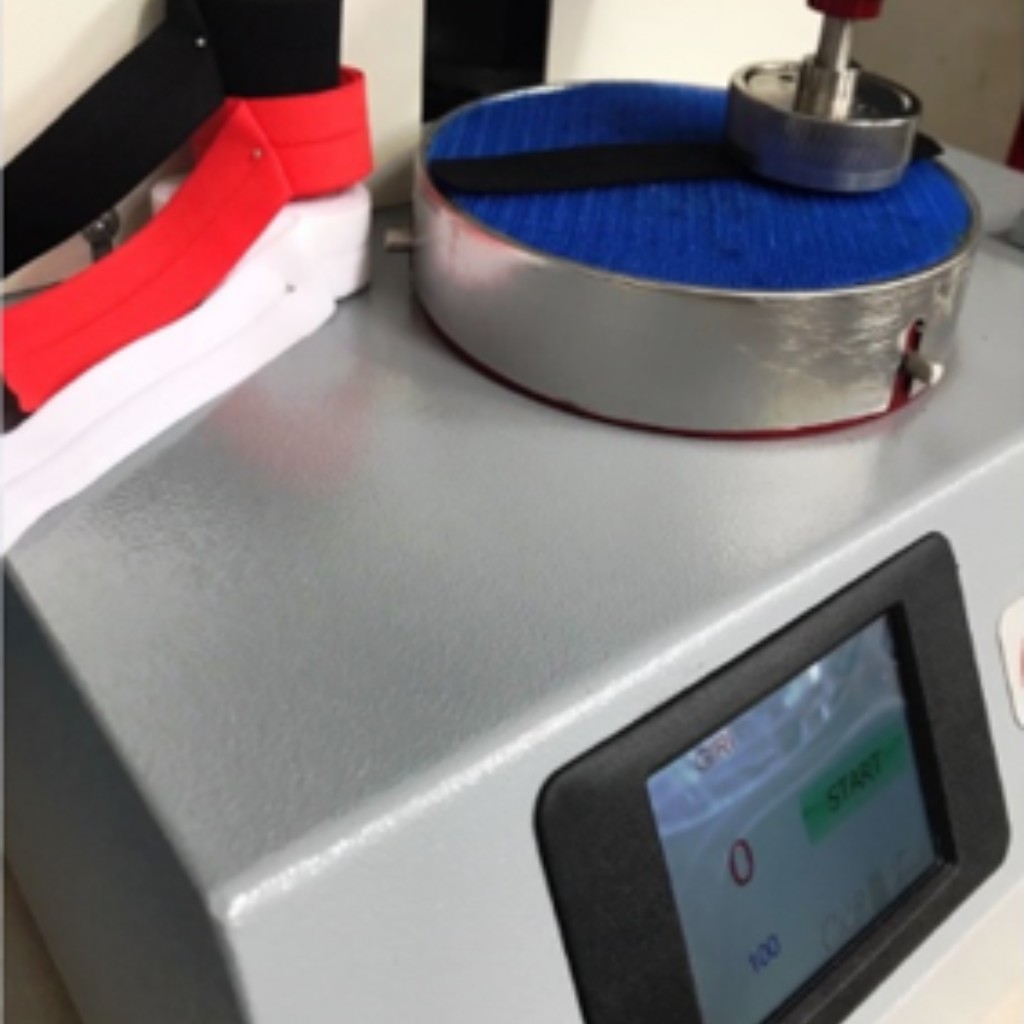

- Exceptional abrasion resistance

- Low moisture absorption and fast drying

- Stable shape retention, even after repeated stress

- A smooth, modern look suitable for outdoor, urban and lifestyle collections

- Availability in black or custom colors

Branding & Technical Upgrades

To support advanced design needs, Art. 5691-20 mm can be enhanced with:

- Hot-stamp branding

- High-definition screen printing

- 3D silicone graphics

- PU laminations: external protective layers or sew-free heat-bondable versions

This transforms a functional trim into a strategic design element that strengthens both performance and brand identity.

Versatile Applications

The material integrates seamlessly into:

- Technical jackets and shells

- Urban outerwear

- Footwear

- Protective gear

- Technical bags and accessories

Built to Last. Designed to Perform.

MAB’s investment in Art. 5691-20 mm reflects a clear commitment: delivering materials that resist abrasion, weather and daily wear while offering designers the freedom to create cleaner, more durable, and more distinctive products.